Omexom in Portugal completes 50-MW solar plant using AI tool

In Sines, a mere 2-hour drive from Lisbon, Omexom Renewables Portugal has completed construction of the Morgavel solar plant. The 100-hectare solar farm features tracker systems whose installation requires a high level of accuracy. An artificial intelligence (AI) tool, AI Clearing, helped ensure precision, quality control, and progress reporting on this innovative and complex project, executed for RWE.

The Sines region, one of the sunniest in the country, is expected to become a renewables and green hydrogen cluster. It provides the perfect setting for a reference project.

Omexom Renewables in Portugal specializes in EPC contracts and Operations and Maintenance contracts for utility-scale solar power plants above 1MW. Last year, they completed the first in-airport solar farm in Portugal at Faro airport.

Morgavel, the young business unit’s second project, is equally unique and much larger in scale.

Built on 100 hectares of land, the equivalent of 100 football stadiums, the plant features 98,832 bifacial high-performance modules mounted on 3,244 single-axis dual-row trackers and 15,381 poles. Commissioned in July 2023, the plant will supply the equivalent of 45,000 households.

A reference project featuring bi-facial panels on tracker systems

Traditional solar plants are composed of fixed tilt structures. They typically face South, at 20 to 25 degrees. Tracker systems are gaining popularity in the Southern Hemisphere, as they move with the course of the sun and allow for optimal absorption of the longer sunlight hours. They are more expensive to build, but compensate with a higher yield, of up to 20 per cent.

In the case of Morgavel, the panels move from -55 to +55 degrees and contain double-sided glass modules which host bifacial cells. They are able to absorb light from both sides, further increasing the yield by 5 to 10 per cent.

This type of system also brings challenges. The first is the availability of land: since panels need to move without casting shadows on each other, they require more distance between them. Additional considerations concern engineering and construction: earthworks, for example, must be extremely precise to ensure the beams are installed in a way that perfectly aligns front and back tracker.

To ensure this level of precision, on a project this large, Omexom Renewables Portugal had one person on site at all times fully dedicated to quality control. In addition, they have chosen to use artificial intelligence technology that reduces the margin of error to 3 cm and eliminates the possibility of human error in reporting.

AI Clearing is a great sales argument. When we show this to a potential client it shows that we have transparency, that they can have the same information as us, in real time. It’s a true added value.

Luís Silva

Business Unit Manager, Omexom Renewables Portugal

Using Artificial Intelligence for quality control, progress tracking and reporting

The construction process, mobilizing up to 200 workers at the same time, was monitored using the AI Clearing platform. This construction technology platform leverages artificial intelligence and advanced GIS (geographic information system) analytics to automate infrastructure construction progress tracking and reporting.

The innovation, supported by Leonard’s CATALYST program, had references from many large-scale solar projects in the United States, and Omexom Renewables Portugal immediately saw the potential of the tool for Morgavel.

After project data and KPIs to be tracked during the project have been defined and input, the AI Clearing solution automizes many of the time-consuming tasks associated with progress tracking and quality management, all while reducing the potential for human error.

Weekly drone inspections collect data with accuracy of less than 2-cm deviation and provide reports within 12 hours, allowing to monitor and rapidly correct any deviation from the project input data.

But also in terms of client relations, AI Clearing adds significant value: the reports are sent to RWE in real time. “In this sense, the tool acts as a neutral third party,” explains Paulo Ramos, Project Manager at Omexom Renewables Portugal. “This approach provides complete transparency towards the client and, with that, establishes trust.”

Up to 200 staff, speaking several languages and with varying degrees of work experience, simultaneously worked on the civil, mechanical, and electrical portions of the project. Three hundred containers were received on site for material delivery. While this creates a lot of movement on-site and an increased risk for accidents to occur, the zero-accident goal has been maintained through a strong focus and investment in safety.

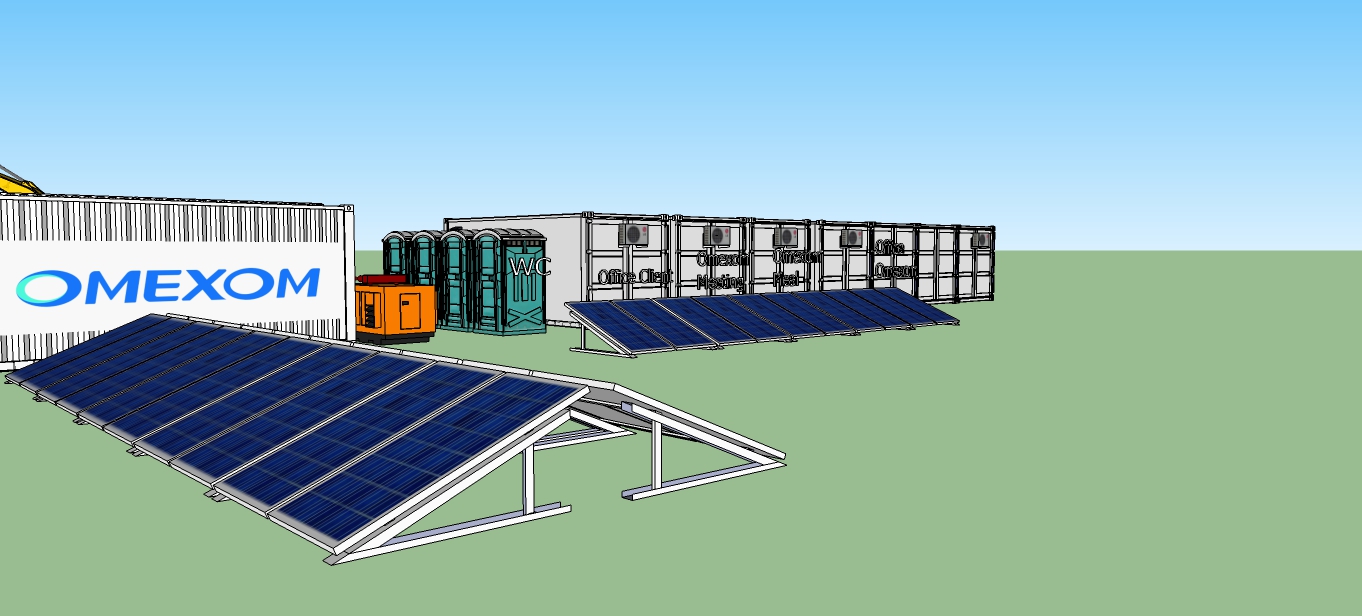

A construction compound powered by on-site solar panels

With the goal of reducing carbon emissions and fuel costs while promoting the use of renewable energies, the teams have launched the Green Container. The entire construction compound comprising 12 containers was powered by the solar panels built on the Morgavel site.

Omexom Renewables Portugal were inspired by plug-in solutions and had researched several providers that sell containers with solar panels already installed, but quickly abandoned this concept and decided to get creative.

“Our idea was to harvest what we already have on site,” said Paulo Ramos. “Why buy something if we can build it ourselves using what we already have?”

The whole project team came together to design and build a system with a dismountable rack that can be mounted on any container and connected to any solar panel.

At Morgavel, it was connected to 32 modules to produce 18 kWp. A battery system will take over at night, while the diesel generator becomes a mere emergency backup.

With their invention, the team has decreased diesel consumption by 92 per cent and reduced carbon emissions by 24,066 kgCO2eq.

In the future, the system can easily be transferred to a different solar project or be combined with extra panels to be used at any construction site.