Webinar InMotion: How 50 Dutch students revolutionize the car racing industry

Electric vehicles are a main part of achieving the energy transition, Omexom’s mission. However, so far, traditional fuel cars represent one feature that prevents adopting electric mobility more widely: convenience. Despite government efforts across Europe, charging stations remain scarce, so reliability is a major challenge. Another one is charging time.

The challenges of e-mobility for race cars

While filling a traditional fuel tank barely leaves enough time for the passengers to take a bathroom break, recharging a typical electric car (60kWh battery) takes roughly 8 hours to charge from empty-to-full using a 7kW charging point.

A minor inconvenience on a family vacation, one would think that charging times make use of e-mobility for race cars, where every second counts during box stops, completely inconceivable.

Wrong. A group of 50 students from Eindhoven University of Technology and Fontys University of Applied Sciences in the Netherlands is here to make fully electric racing the future.

The evolution of Revolution

The story of InMotion goes back all the way to 2009, when three students from Hogeschool Utrecht built the first bio-ethanol race car in the Netherlands. Their graduation project, it was the first step towards eco-friendly racing.

After graduating, one of them, Albert Maas, pursued his study at Eindhoven University of Technology. Shortly afterward, InMotion was created with nine fellow students, with a dream to create the most innovative race car in the world and to one day participate in the 24-hour endurance race in Le Mans.

Since then, the team built several race car models, each time learning more about car and battery design. The construction of the Fusion, the first electric Formula car, started during the academic year 2014-2015 and was completed in 2017. While achieving three lap records, the Fusion takes 45 minutes to recharge after each lap record attempt.

The Vision, based on an original design by Albert Maas five years prior, was revealed in 2018. The InMotion team expanded to 50 members that year to build this concept car which is almost ten times as efficient aerodynamically as a current Formula 1 car.

Then followed the revolution, as in both the name of the car, but also the possibilities that it offers: The two-year design phase of the Revolution began in 2019. The fast-charging endurance race car that was envisioned years back was to finally become reality.

This two-year design phase was followed by another year of assembly, after which InMotion could finally reveal the Revolution to the outside world in 2021. The Revolution’s first milestone is an incredibly fast charging time; During a performance test with the Revolution in 2021, InMotion was able to charge a 57.6 kWh battery pack from 20% to 80% in 12 minutes.

Not fast enough for the ambitious team though, who want to reduce their car’s charging time to exactly the same time it takes to fuel a combustion-powered counterpart: two minutes.

“Recharging an electric vehicle needs to be as easy as refuelling a car. When we achieve that equivalence, electric mobility will have become a reality. [InMotion] have already achieved great milestones in recent years, and we are curious which ones will come.”

Paul Van Schijndel

Business Unit Manager Omexom in the Netherlands

Omexom in the Netherlands: Partner of InMotion since 2019

Omexom in the Netherlands is a Platinum sponsor of InMotion since 2019; a perfect match for Paul van Schijndel, Business Unit Manager, since Omexom’s mission consists in achieving the energy transition and building a sustainable future for all.

“Omexom is keen to address the challenges of e-mobility and electrical infrastructure,” he said, well aware of the obstacles that electric mobility users face today. “Recharging an electric vehicle needs to be as easy as refuelling a car. When we achieve that equivalence, electric mobility will have become a reality.”

For this, Paul has faith in the students. “They have already achieved great milestones in recent years, and we are curious which ones will come.”

“It is a great opportunity that I have not regretted for a moment. I get to contribute to the acceleration of the energy transition within mobility, something that is very important.”

Martijn Scholtus

Student and InMotion Account Manager

In addition to their regular studies, the young adults are running InMotion like a business, with full-time and part-time roles and titles such as account manager, HR manager and finance manager. A professional website provides regular news updates and they are solicited for many events. There is no doubt that InMotion goes way beyond a typical end-of-year project and requires time and commitment.

“It is a great opportunity that I have not regretted for a moment,” says Martijn Scholtus, student and Account Manager.

“On the one hand because it is incredibly educational. I have been able to learn so much in practice and get to know people and companies in a short time. On the other hand, because I get to contribute to the acceleration of the energy transition within mobility, something that is very important.”

Keeping it cool: Designing a race proof battery pack

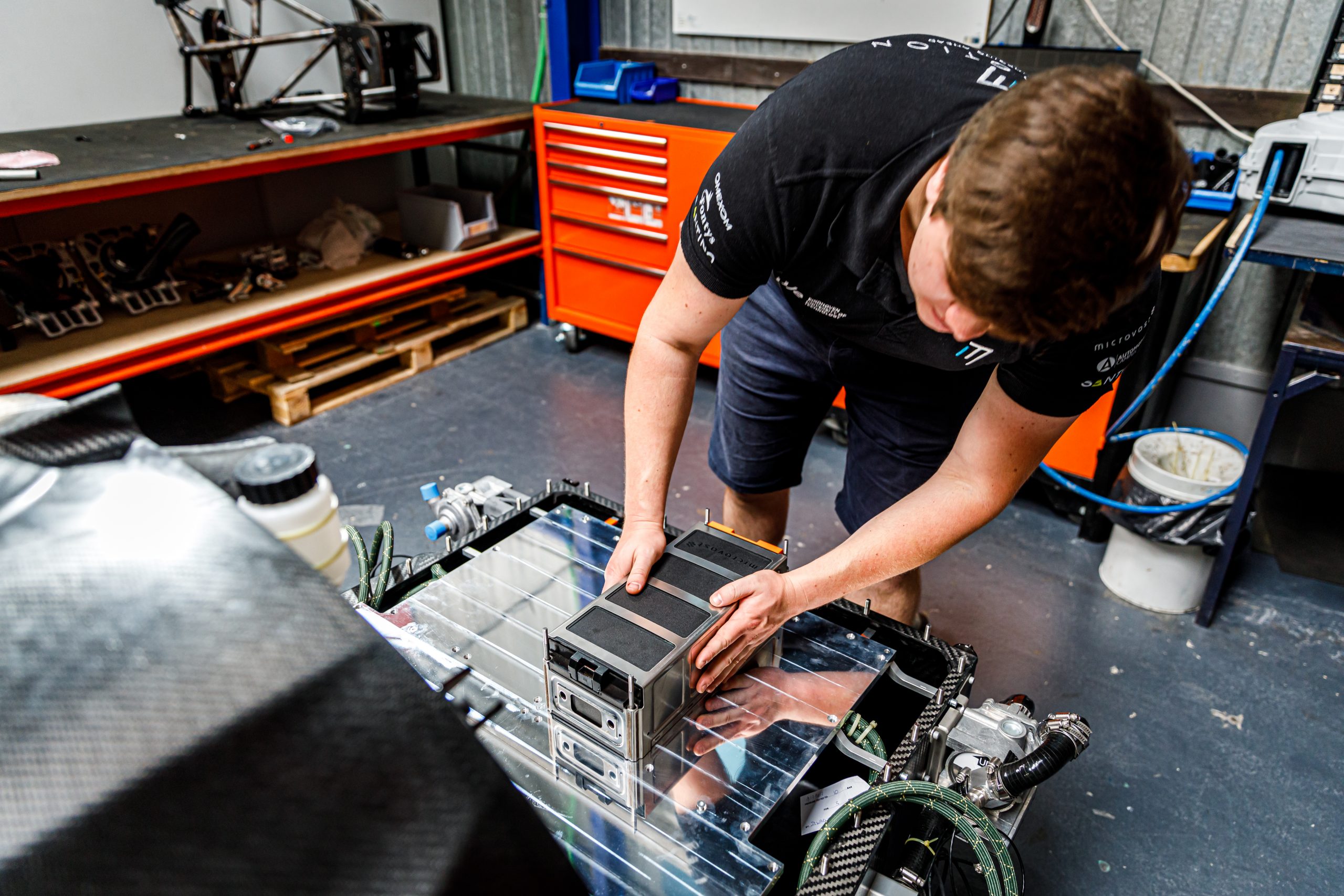

To achieve their objective, InMotion focus above all on the design of the battery pack.

“With fast charging, the battery gets very hot,” explains Martijn. “When an electric battery is in use, the current generates heat inside the cells and the interconnected systems. This heat has a negative impact on the battery, its performance, and the electric vehicle.”

Both charging and discharging of the current create a certain amount of heat, but the strength of the current being proportional to the temperature produced, the moment of charging the car is crucial. In the case of a race car, an overheated battery can damage the car and end the race.

The main challenge for the team therefore consists in finding ways to extract that heat very quickly and cool the battery pack at the same time.

“InMotion focuses on the design of a new battery pack with a cooling system that keeps the system on a constant temperature to make fast charging possible without damaging the batteries and car,” Martijn says.

To reach their goal of participating at Le Mans, the team needs a car with a battery that can be cooled at cell level.

The race of InMotion’s dreams: 24 hours of Le Mans

Why Le Mans?

“The mission of InMotion is to make charging as fast and convenient as refueling a petrol-fueled car. In addition, we want to make EV attractive.

The 24-hour race of Le Mans is a great platform to test and showcase the technology on the one hand and to generate exposure on the other. Furthermore, it is really challenging to be able to participate in such a huge race as a student team. Therefore, our dream remains to participate in the 24-hour race of Le Mans.

To get there, we are going to participate in several big races and events in the coming years to test and prove what we can do and to introduce everyone to our technique.”

– Martijn Scholtus

The annual endurance-focused sports car race of Le Mans is a challenge in its own way in that teams must design cars not only for speed but also endurance and reliability. Naturally this leads to designing fuel efficient cars.

By introducing Garage 56, Le Mans’ organizers are taking an additional step in their vocation of driving technical progress. Introduced in 2012, this slot is reserved for innovative cars. Not part of the official competition the entries are not subject to the technical regulations that are applied to the rest of the competitors, thereby leaving room for, and encouraging, creativity.

Charging ahead: InMotion’s next steps

Currently, the team’s efforts are focused on two things: continuing their work on the Revolution with the current battery back and simultaneously developing the next generation battery pack.

The engineers are working hard to make the Revolution, which can charge in 12 minutes, ready for the race season. They have been doing a lot of research and improvements on the car over the last few months with the goal to be driving in many places in the summer and showcase what they have already achieved.

In parallel, the team is working hard on research for the next generation battery pack. The current battery pack cools on module level. For the next pack, the goal is to develop a system that cools on cell level.

“We are aiming to develop a module this summer that can charge within 7.5 minutes,” says Martijn. “This is huge step forward! During the webinar, we will share more about how we do this.”

What webinar, you ask? We’re glad you did!

“I hope to make people enthusiastic about what we do and about electric racing and that more people will get to know InMotion.”

Martijn Scholtus

Student and InMotion Account Manager

The InMotion webinar powered by Omexom